CSP mini tower developer predicts costs below $50/MWh

Vast Solar's modular CSP tower plant with sodium transfer fluid will be competitive with coal and gas plants at scale and the Australian developer could build its first commercial plant by 2022, Craig Wood, CEO of Vast Solar, told New Energy Update.

Related Articles

Vast Solar recently announced plans to build a 50 MW CSP-PV plant in New South Wales, Australia, which includes 30 MW of CSP capacity and 10 hours of molten salt energy storage capacity.

The A$240 million Reference Plant project represents the first large-scale deployment of Vast Solar's innovative CSP plant design, which features multiple small towers and uses liquid sodium as heat transfer fluid (HTF).

Vast Solar has already built a 1.1 MWe pilot plant in Jemalong, New South Wales consisting of five modules and including three hours of storage capacity. Operational for over a year and fully commissioned in June 2018, the A$24 million pilot plant has undergone extensive testing and Vast Solar predicts major cost savings on larger projects.

The Vast Solar CSP design uses a distributed sodium loop throughout the solar array to achieve higher HTF temperatures and higher power cycle temperatures than conventional central tower designs, Wood told New Energy Update.

Liquid sodium efficiencies, modular build savings and a distributed control system will lower the levelized cost of electricity (LCOE) of larger-scale plants to below US$50/MWh in locations with high direct normal irradiance (DNI) levels, Wood said.

Large-scale plants will be "cheaper than coal and gas-fired plants and other renewable energy storage technologies" and could open up new opportunities in areas with lower solar irradiance levels, he said.

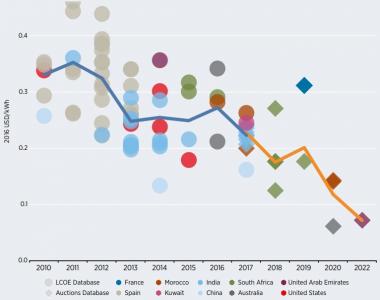

Global CSP cost, auction price trends

(Click image to enlarge)

Source: International Renewable Energy Agency (IRENA), January 2018.

Finance push

Vast Solar is currently seeking A$75 million of financing, including $50 million of equity investment for the 50 MW Reference Plant project and $25 million to fund the business for the next three years.

Securing funding and construction efficiency will be the two main challenges for the project, Wood said.

"We are aiming for financial close by the end of this calendar year and expect a two-year construction duration," he said.

As a first of a kind (FOAK) plant, the project is expected to gain concessional support from Australian Federal and State Governments, Wood said.

The pilot plant in Jemalong received A$9.9 million in funding from the Australian Renewable Energy Agency (ARENA).

"Significant knowledge has been gained from this [pilot] project, especially with regards to constructing and testing a first-of-a-kind facility in a regional location, as well as proprietary knowledge around control systems and the use of sodium as a heat transfer fluid in a solar thermal plant," an ARENA spokesperson told New Energy Update.

Vast Solar has also applied to access the federal government's new Underwriting New Generation Investments (UNGI) program for the Reference Plant, although the nature of this support is yet to be determined and this is not a prerequisite for the project.

The developer has included PV in the project in order to increase daytime output capacity and match regional demand profiles. The PV capacity will also provide faster returns on investment due to shorter construction cycles.

"We expect to consider installation of PV alongside CSP in most situations, but it is not mandatory," Wood said.

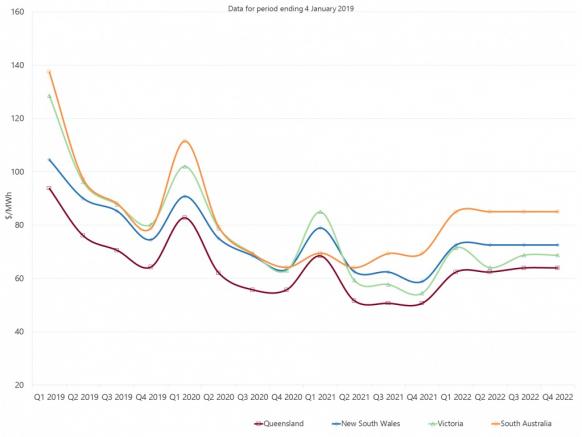

Australia quarterly power futures by region

(Click image to enlarge)

Source: Australian Energy Regulator

A smooth financing and construction process could see Vast Solar overtake SolarReserve to install Australia's first large-scale CSP plant.

U.S. CSP tower developer SolarReserve is currently developing the 150 MW Aurora CSP plant in South Australia and the project has slipped behind initial schedules.

In 2017, the Government of South Australia awarded U.S. developer SolarReserve a 20-year power offtake agreement at a maximum price of A$78/MWh.

Construction is yet to begin and SolarReserve may add PV to the project to improve economics, the company said last year.

Mini towers

The Vast Solar CSP design distributes a sodium loop system throughout the solar array, separating liquid sodium energy collection from molten salt storage.

While the liquid sodium loop raises the cost of piping, valves, pumps and heat exchangers, these are outweighed by the benefits, Wood said.

Costs are offset by “reductions in cost, size and complexity in the solar array, tower, receiver and salt storage systems” as well as improved performance and reduced operational risk, he said.

Compared to central tower designs, modular solar arrays deliver 17% more energy to the receiver for each square metre of mirror, Wood said.

This saves capex costs and "17% less mirrors mean 17% less cleaning – a significant opex saving," he said.

Vast Solar's towers are smaller than conventional designs and use a lightweight steel lattice structure. The towers are assembled on the ground, then tilted into position.

The modular tower and array layout can be constructed in parallel, at the same time as power block or storage construction, reducing total construction time to between 18 and 24 months, Wood said.

The lower height of the towers means they can be accessed via elevated work platforms, simplifying operations and maintenance (O&M) activities.

Modular manufacturing

Vast Solar’s modular design also maximizes off-site prefabrication, cutting on-site construction schedules and risks.

The technology is designed to leverage auto industry techniques and robotic assembly lines, Wood said.

"The heliostat drives, facets, towers, receivers, pipe and valve assemblies and sub-assemblies elsewhere on the plant have been carefully designed to maximize modularity and minimize site works," he said.

Vast solar is "currently finalizing discussions with key suppliers," Wood said.

Several of the major components will be manufactured outside Australia, in countries such as China, U.S. and Czech Republic, he said.

Receiver savings

The Vast Solar plant is operated through a distributed receiver system, which uses the HTF flow as the primary control mechanism, rather than solar flux.

The system allows higher HTF and storage temperatures, increasing efficiency, while also raising energy capture during cloudy weather.

"The mixing effect of distributed receivers significantly reduces temperature variation and ensures that plant-wide transients do not result in a single cold front arriving at the heat exchanger," Wood said.

In dusty or lower DNI environments, the compact solar arrays retain their efficiency better than larger dimension projects, making them competitive in tougher climates such as Middle East and North Africa (MENA), Wood said.

“We simply add more modules to increase thermal output from the plant, negating the effect of increased attenuation or lesser solar resource,” he said.

In lower DNI locations, large-scale plants could achieve an LCOE of US$60-$65/MWh,” Wood said.

“Vast Solar’s technology will make CSP commercially viable in locations that challenge other CSP technologies,” he said.

New Energy Update