Dubai CSP technology inventions accelerate industry cost reductions

Supplier innovations at the 950 MW Noor Energy 1 project will increase construction and operations efficiency and propel the CSP industry closer to $50/MWh, industry experts told the Mena New Energy 2019 conference.

Related Articles

Last month, the Dubai Electricity Water Authority (DEWA), Saudi Arabia's ACWA Power and China's Silk Road Fund reached financial closure on the $4.4 billion Noor Energy 1 CSP-PV project in Dubai.

The 950 MW Noor Energy 1 project includes three 200 MW parabolic trough CSP systems, a 100 MW CSP tower plant, 250 MW of PV capacity and 15 hours of molten salt CSP storage capacity.

DEWA awarded the project in 2017 at a record-low tariff of $73/MWh.

CSP developers are under pressure to reduce costs as PV and wind capacity rises and battery costs fall. The Noor Energy 1 tariff set a new benchmark for CSP, at less than half the price of ACWA Power’s Noor III ($150/MWh) CSP plant in Morocco, brought online last year.

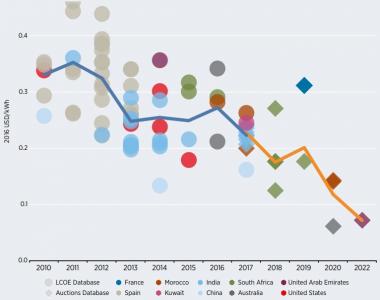

CSP levelized cost, auction price trends

(Click image to enlarge)

Source: International Renewable Energy Agency (Irena), January 2018.

For the Dubai project, developer ACWA Power has used an optimised combination of technology, economies of scale and an innovative 35-year power purchase agreement (PPA) to drive down project costs.

ACWA Power and its lead EPC group Shanghai Electric worked closely with engineers and suppliers to improve design and construction efficiency.

The plant will include first of a kind (FOAK) engineering solutions that will help to lower the cost of future projects, project participants told the conference in Dubai on March 26.

A number of CSP experts said the cost of CSP-PV plants could fall to $50/MWh and some believe a new record-low price will soon be announced.

The bullish predictions come as Morocco, a pioneer of CSP development, prepares to announce the winning tariff for its Noor Midelt CSP-PV project which will include at least 300 MW of CSP capacity and a minimum of five hours storage.

New solutions

CSP suppliers must continue to innovate to fend off competition from other renewable energy types, Georgio Akiki, Business Development Manager - Middle East at SENER, told the conference.

"A lot of the onus comes on the technology providers. We have to keep innovating and reducing costs," Akiki said.

For Noor Energy 1, ACWA Power and Shanghai Electric went directly to suppliers to find ways to increase design efficiency and reduce costs.

"Not only the technology providers, but also suppliers like structure suppliers, even molten salt, everything- we have gone through details, we have negotiated prices with the suppliers," Meriem Bellizim, Business Development Senior Manager at ACWA Power, said.

"There were many suppliers that were keen to enter the market," Bellizim noted.

Belgium's CMI Solar is supplying the molten salt receiver for the 100 MW Noor Energy 1 CSP tower plant.

CMI has already installed its technology at the 50 MW Khi Solar One plant in South Africa, and is supplying its technology to the 110 MW Cerro Dominador plant in Chile and the 50 MW Haixi plant in China.

The CMI receiver is a fully-bolted steel structure which is assembled on the ground and lifted up in one piece, minimising on-site construction work, Jean-Michel Wautelet, Sales Manager at CMI Group, told attendees.

"We do not need to build the receiver on top of the tower...it's quite an added value," he said.

The receiver is also airtight and includes insulated casing behind heat exchanger panels, to improve thermal efficiency, Wautelet said.

"These panels are also bolted, they are....easily dismountable in case you need to perform any kind of maintenance in the receiver," he said.

There are also walkways and ladders inside the receiver structure for easier maintenance access and a 360 crane mounted on top is designed to suspend technicians to access parts via the outside, Wautelet said.

The crane is also capable of lowering one heat exchanger panel to the ground, if required for maintenance, he said.

CMI is continuing to perform engineering operations and is starting purchasing activities, Wautelet said.

BrightSource is supplying the control system for the tower plant and the company has worked hard to lower the cost of solar field operations.

BrightSource CSP tower systems now include fully wireless and self-powered heliostats, Jayesh De Silva, Business Development, BrightSource Energy, said.

In many parts of the Middle East, dust and humidity are a significant challenge for operators, requiring cost-efficient cleaning solutions.

BrightSource is working on automated heliostat cleaning systems for Noor Energy 1, DeSilva said.

"These sorts of innovations will help bring down costs," he said.

Performance targets

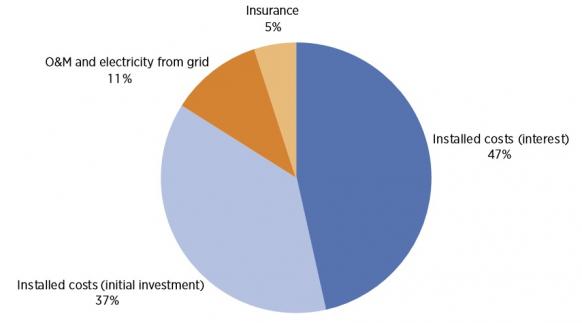

As developers chase lower prices, CSP partners must continue to focus on plant reliability. Installed CSP capacity is relatively low compared with PV and wind technologies, particularly for tower designs. Cost of finance represents a significant portion of CSP project costs and the performance of individual projects remains key to investor confidence.

Levelized cost of parabolic trough plants by segment

(Click image to enlarge)

Source: International Renewable Energy Agency, 2016

ACWA Power's 150 MW Noor III central tower plant in Morocco came online in December 2018 and the performance of this plant will be closely watched by industry stakeholders.

Designed and built by SENER, Noor III is Morocco's first CSP tower and includes 7.5 hours of molten salt storage capacity.

"We are very happy with the performance so far. In the first months we are above what our targets are," Akiki told the conference.

"I think that's alleviating a lot of the concerns on the reliability, especially for towers," he said.

Suppliers to Dubai’s Noor Energy 1 project have had to enhance strength and durability features to ensure reliability throughout the record 35-year power purchase agreement.

CMI has drawn from its design, testing and manufacturing expertise to ensure high performance and durability, Wautelet said.

The CMI receiver will have an outlet temperature of 565 degrees C, currently the upper limits of corrosion thresholds for commercial designs.

The CMI design includes a patented system which protects against receiver panels overheating, keeping the system within temperature thresholds set for both short-term operations and long-term durability, Wautelet told attendees.

CMI has also implemented the highest grade materials and welding processes, Wautelet said.

"This is where we can add some added value. We have a welding expertise centre that is helping to find the best way to weld the different very exotic materials," he said.

U.S. and European researchers are now developing higher-temperature CSP plant designs to increase the efficiency of converting heat to electricity and further reduce CSP generation costs.

In the U.S., three research teams are developing designs which heat transfer fluids (HTFs) to over 700 degrees Celsius (C). The three groups are competing for $25 million of Department Of Energy (DOE) funding to build an integrated demonstrator and commercial exports could begin in the 2020s.

New Energy Update