Siemens to cut offshore maintenance times with labor-saving drones

Siemens and technology firm Skyspecs are preparing to deploy new drones which use a combination of 3D technology and digital data capture to reduce downtimes and labor costs, company executives told Wind Energy Update.

Related Articles

Advances in battery technology, operational algorithms and data analytics are improving the business case for unmanned aerial vehicle (drone) inspections of wind turbines. Drones are becoming more autonomous, potentially creating significant cost savings while improving employee safety.

Technology advancements come as wind farm operators seek new ways to lower operations and maintenance (O&M) costs to compete against other generation types. O&M costs represent up to 25% of the levelized cost of energy (LCOE) of offshore wind farms, according to the UK government’s ORE Catapult research center.

Vattenfall's record-low offshore wind price of 37.2 ore per kWh [49.9 euros/MWh, $53/MWh] for the 600 MW Kriegers Flak project in Denmark has shown how falling costs and competitive tenders are spurring intense price competition in the offshore wind market.

Last month, DONG Energy and ENBW became the first offshore wind power developers to acquire offshore wind power concessions at unsubsidized prices. DONG and ENBW bid prices of Eur0/MWh for a total capacity of 1.4 GW, exposing the projects to wholesale market prices when they are completed in 2024 and 2025.

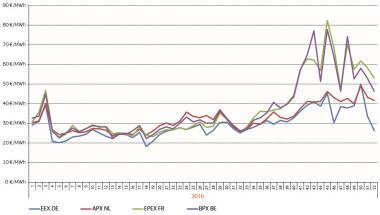

European average weekly wholesale prices

(Click image to enlarge)

EEX DE represents Germany, APX NL Netherlands, EPEX FR France and BPX BE Belgium.

Source: European Commission's Quarterly Report on European Electricity Markets. Data Source: Platts

Labor and vessel costs form a significant part of offshore O&M costs and developers are implementing the latest automated technology and data analytics to improve maintenance planning and reduce downtimes.

Turbine supplier Siemens Windpower has created a joint project with US-based SkySpecs to develop drone technology for offshore turbine inspections.

“The attraction of this deal for us is that for the near future, we see automated blade inspection as an exciting option for a fast, efficient and cost-effective solution compared to traditional inspection methods,” Rudiger Knauf, Chief Technology Officer at Siemens’ Windpower and Renewables, told Wind Energy Update.

The drone technology is designed to achieve a high-speed and high-quality visual inspection, which should lower vessel costs and cut downtimes, Knauf said.

“Images would identify cracks, erosion, lightning strikes and other anomalies…We are currently testing the system at selected sites,” he said.

Rising autonomy

SkySpecs estimates one of its drones can inspect 150 offshore wind turbine towers in around eight days, compared with an estimated three to six months using manual inspections, Danny Ellis, SkySpecs CEO, told Wind Energy Update. A SkySpecs drone takes approximately 22 minutes to inspect a single offshore turbine, while an onshore inspection takes just 12 minutes, he said.

The SkySpecs technology uses a combination of sensors, including LiDAR, GPS and an on-board camera, to set three-dimensional waypoints, which significantly reduces flight time by not requiring blades to be arranged in any particular position, Ellis said. Most other drone technologies in the wind industry use two-dimensional GPS points and require blades to be rotated into certain positions while the drone captures images, he said.

The drone system would be deployed to site from a Crew Transfer Vessel (CTV) and operated by a SkySpecs pilot-engineer, Knauf said.

The entire flight plan and photography would be autonomous, he said.

“In an automated system, pilot error is removed from the equation, and speed and consistency of the image captured during wind turbine inspections could be increased,” Knauf said.

Further improvements should remove the need for a dedicated pilot-engineer and allow windfarm operators to operate the technology, he added.

The rising use of automated technology should significantly reduce offshore O&M costs, since offshore operators incur vessel costs to transfer staff between turbines.

Digital life

The data collected by the drones will provide a "digital timeline" of damage regression and will allow Siemens to incorporate more advanced preventive maintenance techniques and predict lifetimes of related assets, according to the company.

A large number of onshore and offshore wind farm operators now use monitoring technology to perform proactive maintenance and improve plant performance.

Siemens and SkySpecs are initially focusing their drone technology at offshore wind farms as there is greater potential to cut O&M costs than for onshore plants, Knauf said.

Onshore operators can use digital cameras with telescopic lenses mounted on tripods, but this method is more difficult to achieve in a moving seaborne vessel, he noted.

Going forward, rising offshore wind turbine dimensions could further support airborne inspection techniques.

DONG Energy has forecasted turbines of capacity between 13 and 15 MW will be available by 2024. This would be almost double the largest capacities currently available for commercial deployment.

By Richard Wachman